"Man is the measure of all things” (Protagoras, 490-420 B.C.)

Staff Advanced Training

Flash animation, 6.5 MB, ZIP

Click index.html

5 pages, 1.7 MB

4.2 MB

Food and Beverage Packaging Line’s

most productive component: you

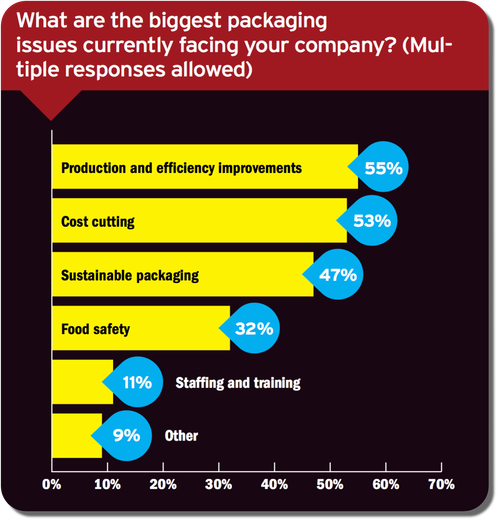

Man is the measure of all things is an idea probably originated in ancient times by the philosopher Protagoras (490-420 B.C.). And whoever living in a Food and Beverage Packaging Line knows how true Protagoras was. Man is the most active part of the Beverage Bottling Line. Its only truly productive component. The effects, positive or negative, are particularly felt for devices, like the Electronic Inspectors, particularly complex and innovative. Bottling Controls are devices implying Staff’s skills prerequisites: an interdisciplinary and operative scientific and technical knowledge, however this facts is commonly hidden to the prospected Buyer by the Vendors. Staffing and training rank fifth in this survey between Food and Beverage Packaging professionals by Clear Seas Research, research arm of BNP Media II publishing the international review Food & Beverage Packaging. The same machinery, the same Bottling Controls, left in the hands of deeply trained staff, because of:

- minimised amount of microstops to production, due to false rejects;

- minimised losses caused by false rejects;

and easily allow a company to fulfill its own Quality Control targets and Policy. Our staff attended tens of advanced-level trainings, on subjects like:

- Optoelectronics,

- Root Cause Analysis and Problem Solving Techniques,

- automation,

- Lines' layout and Conveyors' logic and automation,

in Germany, Italy and France. Countries with 150 year of tradition in Food, Beverage and their Packaging Machinery. Totalling over one year exclusively attending professional-level Food and Beverage Packaging trainings and R&D seminaries.

![]() Staffing and training rank 5th in this survey between Food & Beverage Packaging professionals by Clear Seas Research the research arm of BNP Media II, LLC editing the international review "Food & Beverage Packaging" (credit P. Demetrakakes, 2011)

Staffing and training rank 5th in this survey between Food & Beverage Packaging professionals by Clear Seas Research the research arm of BNP Media II, LLC editing the international review "Food & Beverage Packaging" (credit P. Demetrakakes, 2011)

Over 300 trainings delivered in 39 countries

“...over 300 trainings, of advanced level had been attended by Production, Maintenance and Laboratory Staff of 119 factories worldwide, over 160 Bottling Lines, in 39 countries”

The constant application to the solution of the specific problems of the Beverage Bottling Line Production, Maintenance and Laboratory Staff along over 400 installations and commissionings of Electronic Inspectors built by several Vendors, implied the necessity to always train them deeply, before to leave the sites. To the date, over 300 trainings, of advanced level had been attended by Production, Maintenance and Quality Control Laboratory Staff of 119 factories worldwide. Staff which is maximising exactly in this moment the indexes of Quality and Production efficiency of over 160 Bottling Lines, in 39 countries. All of them, sincerely satisfied by the immediate factual results of these trainings. Staff's new technical awareness, problem-solving capabilities and self-confidence. We have 25 years of experience on advanced training of the packaging factories’ staff. Who are these Customers ? Several Fortune-500 companies like Coca-Cola®, PepsiCo® or Carlsberg®.

Immediate effects

To have a practical idea of what it means to have deeply trained Maintenance Staff in a Beverage Bottling Line, suppose you are managing a glass-returnable or an aseptic filling Line say, the two most complex possible applications of the Electronic Inspectors. Those implying Artificial Vision technologies and Bottling Controls with sensors in-the-Filler or Labeller or Closer Machines, rather than standalone. Prepare yourself to reduce:

- 10 - 100 times the falsely rejected containers;

- 2 - 10 times the size of the defects of the test containers (under filling level, size of test holes, opaque objects in the base of test bottles, cans, crates, etc.). Meaning that if your Staff technical skills are upgraded, the same Quality standards can be easily upgraded.

“I was familiar with weapons, tactics, and war. But years on the battlefield had taught me that soldiering is really about people. Weapons don’t dig muddy foxholes – people do. War plans don’t evacuate wounded comrades – people do. The Pentagon doesn’t create the brotherhood of the Army – people do. What I’d learned, above all other lessons, was the importance of those you surround yourself with”. The text quoted before, by the US Army, General Stanley McCrystal, enforces the paramount relevance of the human-factor with respect to the Machine. It is what we are trying to let be clear. An Electronic Inspector, frequently a device with tens of CPUs parallel processing billions of analog inputs to decide the future of a container, operating over a data base of thousands of parameters, needs humans. Maintenance Techicians and Production Operators truly ready to understand its necessities, priorities and physico-mathematical language. It needs trained Staff in front. Otherwise it shall perform like the worse existing, mere generator of false rejects

Graphene® staff trainings are typically delivered on-site and closer than possible to your Electronic Inspectors. Tailored to the models and kind of packaging your are handling by mean of thjem. They always imply a massive multimedia support: specific softwares and videos best shown by mean of a video projector (also named videobeam, made available by you) connected to our computers. The subjects are all those you can see treated in this web site. One-half of the time Theory and the other half Practical exercises directly over the Electronic Inspectors, learning how to:

- adjust the parameterisations defining their sensitivities and mask positions;

- maintenance their Optoelectronics systems and devices;

- create an industrial Ethernet network, so to extend the awareness of the Inspectors’ function in near real time to Production and Maintenance managers;

- diagnose faults and service the inner hardware and Electronics;

- maintenance their mechanical parts;

so to reach and easily maintain along years, those top performances otherwise reachable only by a expensive external Specialist operating on-site. In the reality, to care your interests, the know-how has to be resident in your Staff, and not out of the factory. Staff trainings exist in any of the languages on right side. PDF or hardcopy documentation is always available in English language and, for the majority of the applications, also in Spanish and French. The trainings’ schedule and timetable is decided by You, on the base of how many shifts you want to be trained and of the level of technical depth you want to be reach. On our side, we’ll adapt with pleasure to fulfill your necessities.

Those who attend courses will receive

- documentation, in PDF-, CD- or paper-way, following your choice;

- personalized pens, notebooks, caps, shirts and gadgets;

- a Certificate of Course Completion.

Pricing

Last, but not least, knowing how vital is know-how, we prefer to keep purportedly the pricing particularly low. This, in benefit of the future of the Bottling Lines and of your right, after so many efforts on your side, to have the maximum satisfaction by the Line. Feel free to contact us, explain your goals and be sure they’ll be rapidly reached !

Contact